rexroth hydraulic solenoid valve for cold roll machine

Basic Info

Model No.: 4WE6

Product Description

Product Description rexroth Hydraulic Solenoid Valve for cold roll machine German rexroth manufacturing process technology parameter :

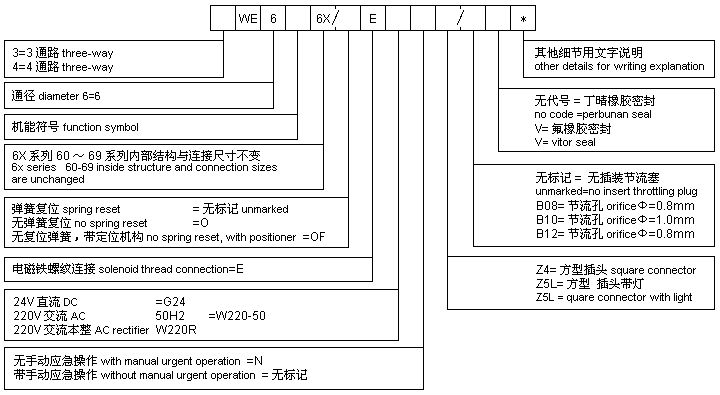

| WE6 type 6x series wet solenoid operated Directional valve NG 6 pressure up to 31.5 Mpa flowrate up to 80 L/min | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Model description | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

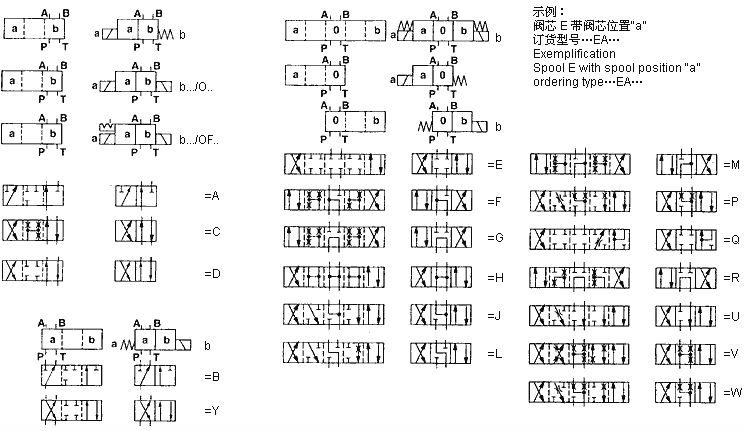

| Symbol | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Principle of operation | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| WE type directional Control Valve is operated by the solenoid to control flow direction and on-off the valve is mainly comprised of valve body (1) one or two solenoids (2) control spool (3) and one or two reset springs(4) When cutting off electricity the control spool(3) is on center or original position by reset spring (4) cexcept for pulse valve The control spool(3) is operated by wet solenoid(2) To ensure for obtaining satisfied with operation, the pressure cavity of solenoid must be filled with oil. The force of solenoid(2) going through rod (5) is acting on control spool (3) it will push on required position while on static position. The oil freely flows from P to A, B, to T P to B or A to T When the solenoid (2) off the control spool(3) will be pushed on original position by reset spring(4) For selection of manual urgent operation (6) can control the spool (3) motion when the solenoid is off 4WE 6..6X/O…type (only limiting symbol A.C.D) The type consists of two switching positions and two solenoids without positions directional control valve 4WE 6..6X/OF…(pulse valve, only limiting symbol A.C.D) It consists of two switching position two solenoide and one positioner directional control valve Two switching positions are respectively fixed so the solenoid needn't requiring for long time woking Insert throttling valve (4WE 6..6X/…/B..) Because of especial working state when switching it may appear as exceeding function curve of allowance flow under this condition it needs to mount insert thnttling plug The plug is mounted on P port of directional control valve. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Technical paramter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

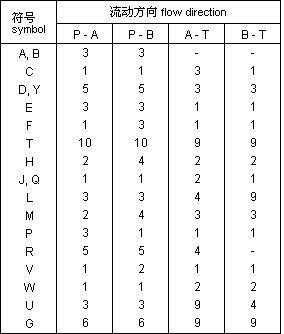

7 symbol “R”is on switching position A-B 7 symbol “R”is on switching position A-B8 symbol “G”and “T”is on center position P-T Switching function limit (be measured when ν=41mm2 /s t=50°C) Working limit for giving is useful for two direction flowing condition (as for P port flow to A of returning of B to T at the same time ) When single direction flow (if the port from P to A B is plugged )because of flow strenth in the valve allowance switching limit may fall cloun Working limit is measured when solenoid is on working temperature owing volt 10% and the reservoir without bearing pressure

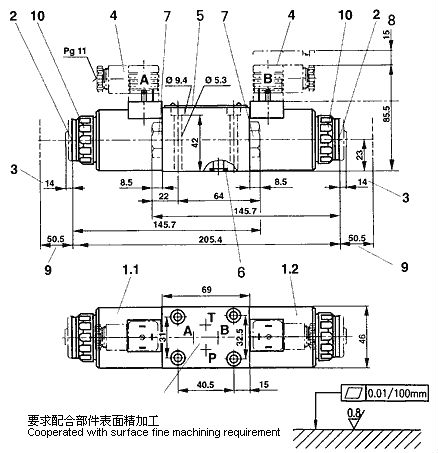

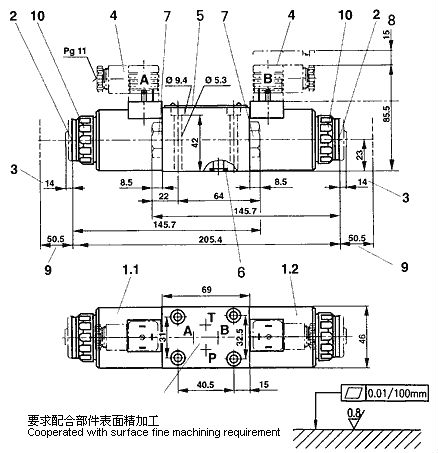

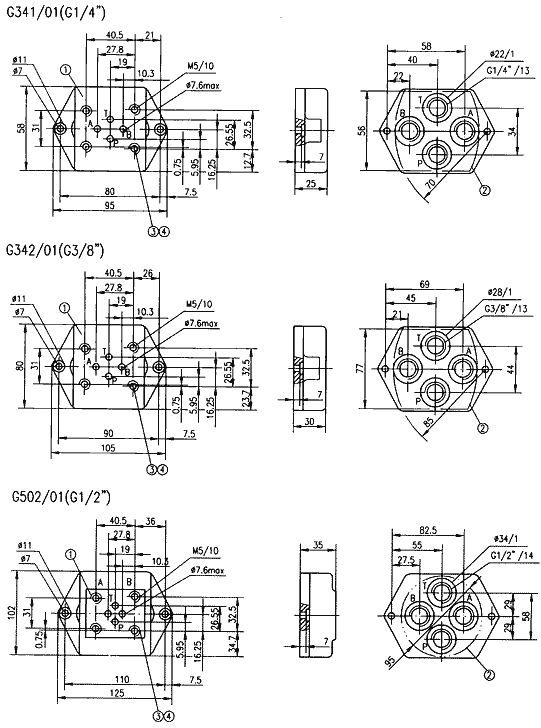

External dimensions: valve with DC solenoid cooperated with surface fine machining requirement External dimensions: valve with DC solenoid cooperated with surface fine machining requirement  1.1 Solenoid “a”(grey plug-in connector) 1.1 Solenoid “a”(grey plug-in connector) 1.2 Solenoid “b” (black plug-in connector) 2. Manual urgent operation 3.Size of solenoid “N”with manual urgent operation 4.Plug-in connector according to DIN43650 5.Name plate 6.O-ring 7. For use one plug of solenoid valve 8. Take off plug-in connector for space request 9. Take off coil for space request 10. Fixed screw nut tightened torque M =4Nm 11.Mounting surface according to DIN24 340, A type ISO 4401 and CETOP-RP 121 H bed plate G341/01(G1/4”) G342/01(G3/8”) G502/01(G1/2”) Fixed screw of the valve M5X50 GB70-85-10.9 Tightened torque MA=8.9Nm External dimensions: valve with AC solenoid cooperated with surface fine machining requirement  1.1 Solenoid “a”(grey plug-in connector) 1.1 Solenoid “a”(grey plug-in connector)1.2 Solenoid “b” (black plug-in connector) 2. Manual urgent operation 3.Size of solenoid “N”with manual urgent operation 4.Plug-in connector according to DIN43650 5.Name plate 6.O-ring 7. For use one plug of solenoid valve 8. Take off plug-in connector for space request 9. Take off coil for space request 10. Fixed screw nut tightened torque M =4Nm 11.Mounting surface according to DIN24 340, A type ISO 4401 and CETOP-RP 121 H bed plate G341/01(G1/4”) G342/01(G3/8”) G502/01(G1/2”) Fixed screw of the valve M5X50 GB70-85-10.9 Tightened torque MA=8.9Nm Connection bed plate  1.Connection surface of the valve 2.Plate tangent 3.Fixed screw of the valve 1.Connection surface of the valve 2.Plate tangent 3.Fixed screw of the valve 4. Fixed screw of the valve four pieces M5X50 GB70-85-10.9 torque 9N.m Valve pictures:  Packaging & Shipping How are orders packed and shipped? Depends on customers' orders. All goods are packed with a plastic bag with an outer carton and a wooden pallet( fumigation). Can be customized according to customer requirements Our Services Raypoo Service We provide hydraulic, lubrication, pneumatic technology consulting, system design, and the parts. Could Raypoo offer OEM service? Yes. Raypo is able to offer OEM with customers' brand name and trademark onto the product. Do Raypoo products come with a warranty? Yes.Raypoo offer 1-year guarantee without abusive usage on all purchases which begins with the bill of lading. Company Information Shenzhen raypoo is a manufacturer of hydraulic products and engineered solutions serving the fluid power market. The Company offers an engineering and manufacturing team capable of providing advanced technology in the design and production of unique fluid power components and electronic controls. The Company's involvement focuses its expertise on markets in which customers demand top quality, prompt delivery, high performance and responsive aftermarket support. The Company's products include piston pumps, motors, valves controls manifolds, ,cylinders, Industries that use these products include primary metals, machine tool, automobile, petroleum, construction equipment, chemical, plastic, glass, lumber, rubber and food. The Company strives to serve those markets requiring high technology and expertise where reliability, top performance and longer service life are needed. The products are sold as individual components or integrated into high performance applications. Packaging & Shipping How are orders packed and shipped? Depends on customers' orders. All goods are packed with a plastic bag with an outer carton and a wooden pallet( fumigation). Can be customized according to customer requirements Our Services Raypoo Service We provide hydraulic, lubrication, pneumatic technology consulting, system design, and the parts. Could Raypoo offer OEM service? Yes. Raypo is able to offer OEM with customers' brand name and trademark onto the product. Do Raypoo products come with a warranty? Yes.Raypoo offer 1-year guarantee without abusive usage on all purchases which begins with the bill of lading. Company Information Shenzhen raypoo is a manufacturer of hydraulic products and engineered solutions serving the fluid power market. The Company offers an engineering and manufacturing team capable of providing advanced technology in the design and production of unique fluid power components and electronic controls. The Company's involvement focuses its expertise on markets in which customers demand top quality, prompt delivery, high performance and responsive aftermarket support. The Company's products include piston pumps, motors, valves controls manifolds, ,cylinders, Industries that use these products include primary metals, machine tool, automobile, petroleum, construction equipment, chemical, plastic, glass, lumber, rubber and food. The Company strives to serve those markets requiring high technology and expertise where reliability, top performance and longer service life are needed. The products are sold as individual components or integrated into high performance applications.      FAQ Q.How to request a manufacturing quotation from Raypoo? A.Give us a call or send us an E-mail with your purchase request. Q.What are your quality control procedures? A.Raypoo is equippedwith high-tech, advancedcomputerized and self-inspection machineries, manufactures thousands of different parts in house to ensure the built-in quality and dependable performance. This is the reason why Raypoo is recognized as on the world class quality level. Contact us if you need more details on Rexroth Hydraulic Solenoid Valve. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Rexroth Hydraulic Solenoid Valve、Rexroth Hydraulic Solenoid Valve. If these products fail to match your need, please contact us and we would like to provide relevant information. FAQ Q.How to request a manufacturing quotation from Raypoo? A.Give us a call or send us an E-mail with your purchase request. Q.What are your quality control procedures? A.Raypoo is equippedwith high-tech, advancedcomputerized and self-inspection machineries, manufactures thousands of different parts in house to ensure the built-in quality and dependable performance. This is the reason why Raypoo is recognized as on the world class quality level. Contact us if you need more details on Rexroth Hydraulic Solenoid Valve. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Rexroth Hydraulic Solenoid Valve、Rexroth Hydraulic Solenoid Valve. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Hydraulic Valves > Directional valve Premium Related Products Other Products

Hot Products m4 m6 m8 m10 m12 air hose fittingsSC pneumatic cylinder is applied to the used shopping bag making machineHSG long stroke hydraulic cylinders2FRM16 beijing huade hydraulic flow control valve speed regulation valve5 2 solenoid valve pneumatic air valve 24vHydraulic plate belt slitting machine hydraulic power station25VQ vickers hydraulic vane pumps for hydraulic plate belt slitting machinehydraulic rotary device for hydraulic trenchless drilling righydraulic throttling valvedirection type two-way logic valve cover plate40my cy14-1b hydraulic pumpIPG hydraulic internal gear pump for hydraulic injection molding machinedg4v vickers hydraulic valve for hydraulic injection molding machineyuken bg-06 high pressure hydraulic relief valve for hydraulic injection molding machinechina NXQ bladder accumulator for hydraulic injection molding machineTwo - way Cartridge proportional throttle valve | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||