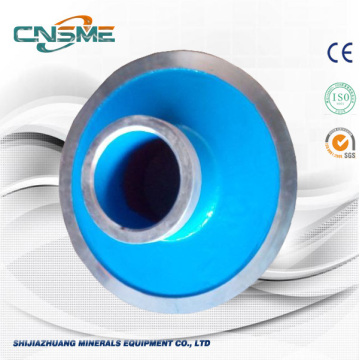

High Chrome Cast Iron Front Liner

Basic Info

Model No.: E4083A05

Product Description

High Chrome Cast Iron Front Liner

Introduction:

The front liner to one of the flow parts of slurry pumps. It binds and forms a liner plate pump chamber for an impeller. As part of the flow, its material is very important and Excellence Pump provides high-chromium white iron (27% chromium) liner to the front, which is very wearable.

1 . Science is based on hydraulic design theories;

2. Strict proihvoditelnye procedures and special inspectors;

3. Various materials for various applications;

4 . Long service life.

A brief introduction of the slurry pumps we offer:

Slurry Pump Series:

1. Metal Lined Slurry Pump, SH Type; 2. Rubber Lined Slurry Pump (SHR Type); 3. Hi-Pressure Slurry Pump (SBH Type);

Gravel Pump Series:

1. Hard Metal Sand Pump (SG, SHG Type); 2. WN Dredging Pump (WN Type);

Sump Pump Series:

1. Metal Vertical Slurry Pump (SV Type); 2. Rubber Vertical Slurry Pump (SVR Type);

Local Pump Series:

1. Power Plant Slurry Pump (ZBG Type); 2. Coal Washing Slurry Pump (ZJ Type);

Froth Pump Series

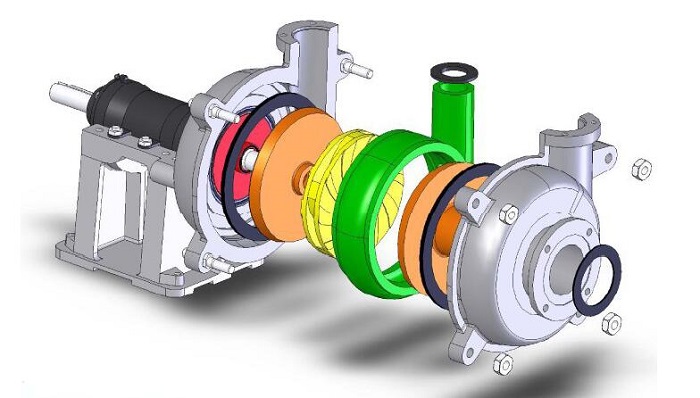

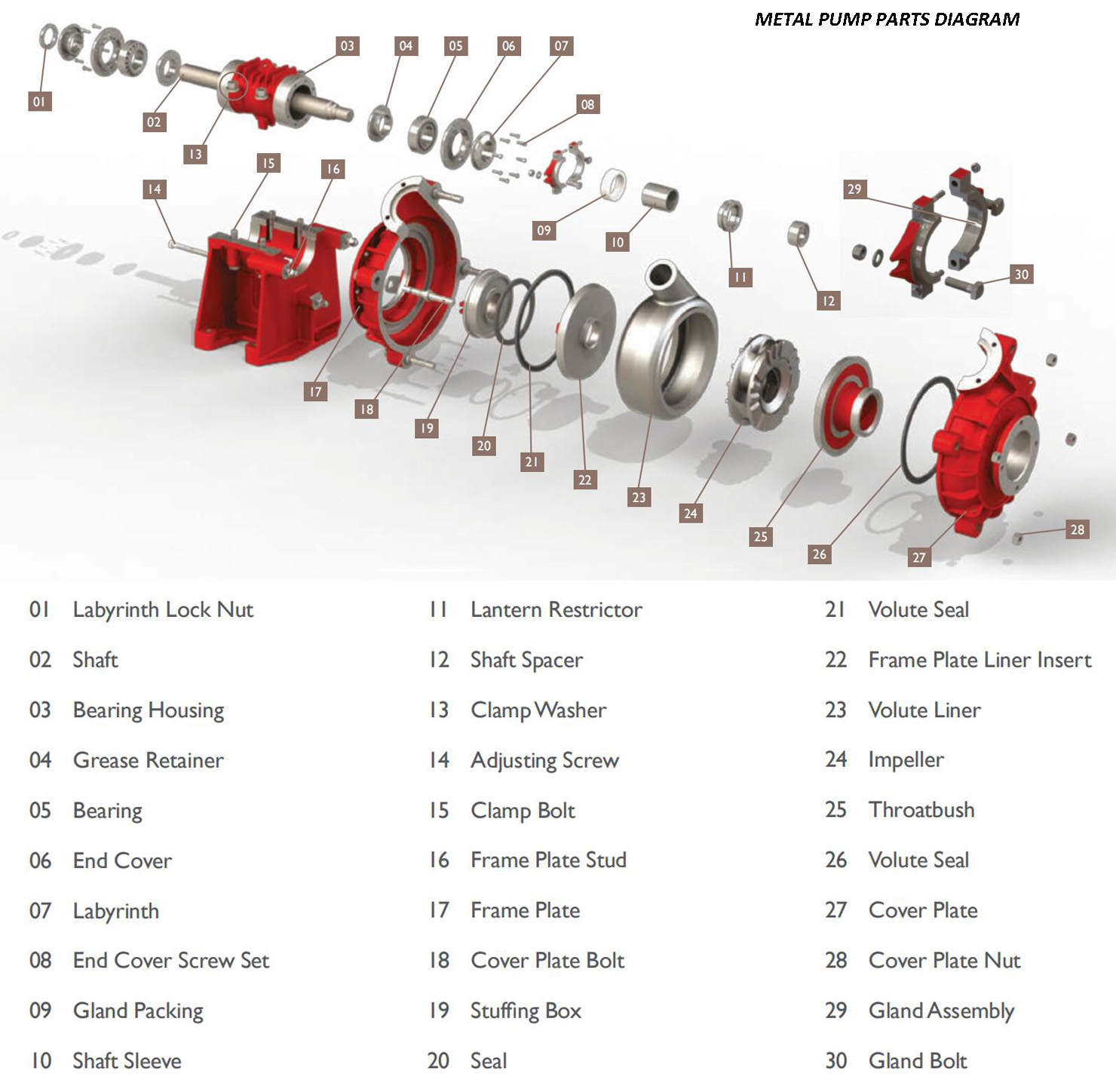

Metal Lined Slurry Pump Construction:

Orders of Slurry Pumps:

Product Categories : Slurry Pump Parts > Metal Pump Parts